High Pressure Common Rail fuel system components on the main

I. Introduction

Common Rail fuel injection system in the 20th century in the late 1990's formal entry into the practical stage. Such electronic control system can be divided into: Accumulator-Electronic Fuel Injection System, electric hydraulic pressure control system and high-pressure fuel injection electronically controlled common rail fuel-injection system. High Pressure Common Rail system can be realized in the traditional fuel injection system can not be achieved in the function of its advantages:

A. Common Rail Injection System of flexible adjustable pressure on the different conditions can determine the best injection pressure required to optimize engine performance.

B. can be independently controlled fuel injection is flexible, with a high injection pressure (120MPa to 200MPa), which can control NOx and particulates (PM) in the smaller numerical in order to meet emission requirements.

C. Flexible control injection rate changes achieve the desired fuel injection law, easy to implement pre-injection and multiple spray can reduce NOx diesel engine can ensure that the good momentum and economy.

D. by the solenoid valve control fuel injection, the control high precision, high pressure Oil bubble and there will not be zero residual pressure and, therefore, in the operation of the diesel engine, fuel injection cycle changes in the volume of small, non-oil tank uniformity can be improved, so as to reduce engine vibration and reduce emissions.

As high pressure common rail system with the above advantages, diesel engine research institutions at home and abroad have invested a lot of energy to study it. More mature system: Germany ROBERT BOSCH company's CR system, Japan's Denso Corp. ECD-U2 system, the Italian FIAT Group unijet system, the United Kingdom DELPHI DIESEL SYSTEMS companies LDCR systems.

Second, high pressure common rail fuel injection system on the main components

Figure 1 is a high pressure common rail fuel injection system, control the basic diagram. It mainly by the electronic control unit, high-pressure pumps, the common rail, electronically controlled fuel injection sensors, as well as various components. Low pressure fuel pump fuel importation of high-pressure pumps, high pressure pump pressurized fuel oil into high-voltage rail, high pressure oil track from the pressure of ECU track under the oil pressure sensor tracks the oil pressure and the need for regulation, high pressure oil in orbit After high-pressure fuel pipeline, according to the operational status of machinery, electronic control unit from the default map plans in the identification of suitable injection timing and injection duration of the electro-hydraulic control of the electronic fuel injector will be injected into the cylinder.

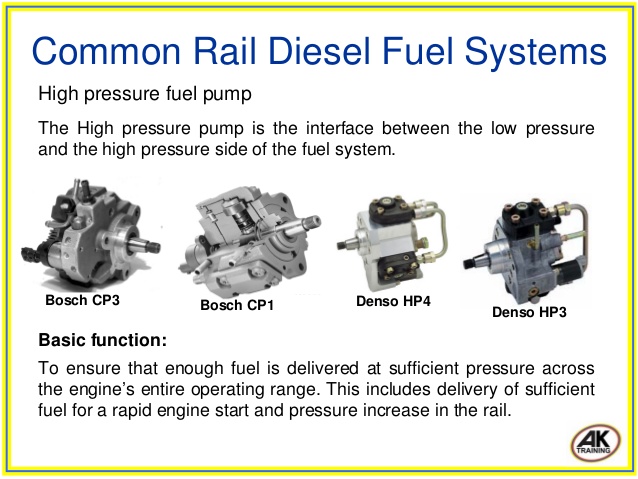

1, high pressure pump

The supply of high-pressure oil pump design criteria must be guaranteed in any circumstances, the diesel engine fuel injection quantity and control of oil and demand, and to accelerate the start-up and the demand for oil changes. The injection pressure in the common rail systems in the fuel injection process have nothing to do, and the injection timing was no high-pressure pumps from the cam to ensure that, the high pressure pump oil pressure according to the peak torque cam minimum, the smallest and most contact stress tolerance Mill design principles to the design of the cam.

Bosch companies from diesel-driven triplex radial piston pump to generate up to 135 Mpa pressure. In each of the high-pressure pump oil pressure unit used in a number of oil pressure cam to reduce peak torque to the traditional high-pressure pumps 1 / 9, also load more evenly, and reduce operating noise. The high-pressure common-rail system in the cavity pressure control through the cavity of the common rail fuel in China to achieve the release, in order to minimize power loss in the fuel injection quantity is smaller, will be closed triplex radial column Cypriot pump oil pressure in one unit to reduce supply.

Denso Corp., introduced a three-line role cam to generate high-pressure pump, as shown in Figure 2. The high-pressure fuel pumps on the low-pressure control used to control fuel oil into effective method.

A plunger down, control valve opened, the low pressure fuel control valve plunger cavity flows;

B plunger up, but not yet in the control valve electricity, in the open state, low fuel by the return of low pressure control valve cavity;

C reach of regular supply, the control valve electricity, closed, returning Circuit was cut, and the plunger cavity compressed fuel, fuel oil, as a high-pressure valve oil into the orbit. Use control valve closing time of the different control access to the high-pressure fuel oil track of how much control high-pressure oil to achieve the purpose of rail pressure;

D-cam or a maximum after the plunger into the fall trip, reducing the pressure on the plunger cavity, filling valve closed, and stop oil supply, the control valve then stop electricity, in the open state, low fuel into the plunger cavity to the next a cycle.

The method of high-pressure pumps do not produce additional power consumption, but the need to identify the control pulse width and pulse control and high-pressure pump cam phase relationships, the control system is rather complicated.

2, the Common Rail

Common Rail will be for the provision of high-pressure fuel pumps assigned to each injector, the pressure has been for the role of ECD-U2 system for the track shown in Figure 4. It should cut the volume of the high-pressure oil pump pressure fluctuations and each injector fuel injection process caused by the pressure shocks, high-pressure oil to track fluctuations in the pressure control in under 5 Mpa. But its volume is not too big so as to ensure that there is sufficient pressure common rail speed response to fast-track the status of the diesel engine for change. ECD-U2's high-pressure pump system the largest circulation for the supply of 600 mm3, the volume of 94,000 common rail mm3.

High Pressure Common Rail also installed tube pressure sensors, flow buffers (current limit) and pressure limiter. ECU pressure sensor to provide high-pressure oil-track pressure signal; flow buffers (current limit) guarantee in a fuel injector leakage failure to cut off the supply to the injector, and reduce common-rail and high pressure in the pipeline the pressure fluctuations; pressure on the high-voltage limiter ensure that the oil pressure in the event of abnormal rail, rapid rail will be in the high pressure oil to put pressure on China.

From the above analysis that, precision design of the High Pressure Common Rail for determining the volume and shape of the diesel engine is not easy.

3, Electronic Fuel Injector

Electronic Fuel Injector Common Rail fuel system is the most critical and most complex components, ECU its role under the control signal sent by controlling the electromagnetic valve open and closed, high-pressure fuel oil track best Injection timing, and injection of diesel engine fuel injection rate is injected into the combustion chamber.

BOSCH ECD-U2 and the electronically controlled fuel injection similar to the structure are similar to the traditional injector nozzle of the control piston, control of holes, control solenoid valve components, Figure 5 for the electronically controlled fuel injection BOSCH Structure plans. No electricity in the solenoid valve, solenoid valve closure of the top of the control piston-A, high-pressure fuel rail pressure oil through hole of Z role in the control piston, the nozzle will be closed when the solenoid valve electricity, of A Hole opened , the control room quickly lower the pressure, control piston rises injector fuel injection began when closed solenoid valve, the pressure of increased control room and control the Pistons closed down injector fuel injection process completed.

Control of the fuel injection rate of the shape of its reasonable to optimize the design, implementation scheduled injection shape. Control Room size determines the volume of the sensitivity of the valve opening, the control room of the volume too much, at the end of the needle injection in the broken oil can not be achieved quickly, so that the latter part of the fuel atomization bad; volume control room is too small, not to provide adequate and effective needle trip to the blasting process flow resistance increased, the volume of the control room should also be in accordance with the largest models Injection Quantity reasonable choice.

A volume-control, Z the size of the nozzle opening and closing speed and the fuel injection process plays a decisive impact. Double hole in the valve body structure into three key oil hole to hole oil and the control room, their structure and size of the injector fuel injection performance enormous impact. Oil back into the hole and the fuel flow rate-the difference between the volume control room and the decision to open the nozzle needle speed, and speed the closure of the valve nozzle from the oil hole into the flow rate and volume control room decision. Hole-fuel nozzle needle should be designed so that there is sufficient closure speed, in order to reduce post-atomized spray nozzle bad part.

In addition the minimum injection pressure nozzle back on fuel oil into the hole and hole control the flow rate and the end of the Pistons. In determining that the fuel into the hole, back to the control room and fuel-size structure, the nozzle needle to determine the stability of completely open, the shortest injection process, the nozzle at the same time to determine the stability of the smallest injection . Volume control room so that the valve can be reduced faster response to temperature on the fuel injection nozzle of the impact of even smaller.

However, the control room could not unlimited volume reduction, it should be able to guarantee the nozzle needle so that the valve lift completely open. Two control of the decision-dynamic pressure in the control room to determine the movement of the needle, through careful regulation of the two hole discharge coefficient, can produce the ideal fuel injection law.

Because of the high pressure common rail injection system is very high injection pressure, so the spray nozzle hole sectional area of the small companies such as BOSCH the spray nozzle hole diameter of 0.169 mm �� 6, in such a small nozzle diameter and such a high The injection pressure, the fuel flow in extreme instability, oil spray cone beam angle, better fuel atomization, but through distance smaller, it should change the original diesel engine inlet swirl intensity, and combustion chamber shape best to ensure that the combustion process.

The injector solenoid valve, common-rail system requirements it will have sufficient speed to open, taking into account pre-injection diesel engine performance is to improve an important injection, the control solenoid valve response time should be shortened. Electromagnetic valve on the larger study has been reported in the literature, this article is no longer this analysis.

4, high-pressure pipeline

High-pressure tubing is connected electronically controlled common rail fuel injection tube and with the access, it should have sufficient fuel flow, fuel flow decreases the pressure drop, high pressure piping systems and pressure fluctuations in the smaller, can withstand the high pressure fuel impact, and at the start the pressure in the common rail can be quickly established. The high-pressure cylinder the length of the pipeline should be equal to a diesel injector each have the same injection pressure, thereby reducing engine cylinder of the deviation between the injector. The high-pressure pipeline should be as short as possible so that the nozzle from the common rail to the minimum pressure loss. BOSCH's foreign economic relations for the high-pressure pipeline of 6 mm diameter was 2.4 mm, Japan, the company installed the high-pressure pipeline foreign economic relations of 8 mm, 3 mm diameter.

3. CONCLUDING REMARKS

As High Pressure Common Rail fuel injection system with the injection timing can be, and the duration of injection, injection pressure, injection of a flexible regulation, the system will enable the use of the diesel engine of the economy, power and emissions performance will have further raised. This requires that we intensify the High Pressure Common Rail System of intensity, the level of China's diesel engine enter a new stage.